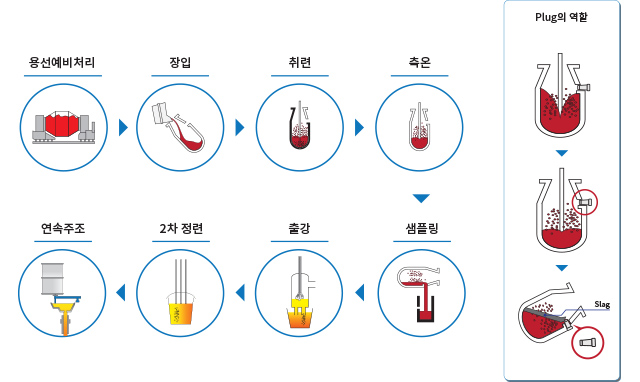

Ceramic Part

A tap hole plug improves the steel quality and reduces aluminum deoxidization of alloy in the ladle, ensuring the slag floatation time through formation of in-core pooling during the converter tilting

- 1) minimization of slag forming in early refining process

- 2) effective slag control improves the durability of refractories used for the tap hole, ladle and secondary refining process by preventing the refractories’ from erosion

- 3) Eco-friendly to prevent air contaminants from the tap hole

- 4) Protecting the BOF (Basic Oxygen Furnace) tap hole

- 5) Extending the BOF tap hole

- 6) Protecting spiting in the early BOF process, enhancing the ladle life

- 7) Ensuring the safety of operators by protecting spiting during the BOF process

Korea

Korea