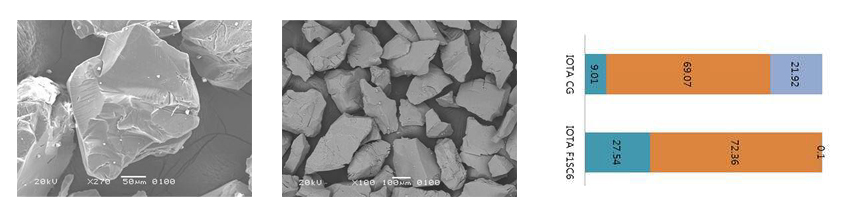

Quartz Part

The major usage of high purity silica sand isbase material of the quartz crucible for solar silicon single crystallineingot and quartz ware for semiconductor manufacturing process.

For the quartz crucible and quartz ware, over 4N (99.99%) degree of purity and under 50ppm of metal impurities are required to prevent the contamination of polysilicon and semiconductor product. This type of high purity sand has been supplied from American and Norway, so no supplier available in the domestic market.

K-TECH will be the pioneer in silica sand manufacturing business in South Korea with the Research Institute of Industrial Science and Technology (RIST)’s raw material production technology for solar energy industry.

Dr. Kim, JongHo, a senior researcher in RIST metal material development team, has successfully improved the manufacturing efficiency, through a three year long challenge since 2012, to integrate the existing process with thermal processing technology, acid treatment and thermo-chemical conversion.

The silica mineral, raw material of silica sand is easily crushed and finely filtered through extreme heat treatment and rapid cooling process to cause the internal breakage in the silica mineral.

Dr. Kim and his research team have reduced several stages of multiple impurity treatment process by one, using the mixture of hydrochloric acid and hydrofluoric acid.

It isvery difficult to remove impurities through the acid treatment have been effectively under control with chlorine and hydrogen chloride so as 30% of unit cost is reduced.

source : http://www.etnews.com/20160812000306

Korea

Korea